The strong industrialization of our processes and the strict controls throughout the production chain allow us to ensure a high level of quality in the final product.

Some specific processes that help guarantee the highest quality of our components include oven painting, vacuum resin impregnation, TIG or ultrasonic welding of output terminals, and thermal crimping for Litz wire.

The strong industrialization of our processes and the strict controls throughout the production chain allow us to ensure a high level of quality in the final product.

Some specific processes that help guarantee the highest quality of our components include oven painting, vacuum resin impregnation, TIG or ultrasonic welding of output terminals, and thermal crimping for Litz wire.

The strong industrialization of our processes and the strict controls throughout the production chain allow us to ensure a high level of quality in the final product.

Some specific processes that help guarantee the highest quality of our components include oven painting, vacuum resin impregnation, TIG or ultrasonic welding of output terminals, and thermal crimping for Litz wire.

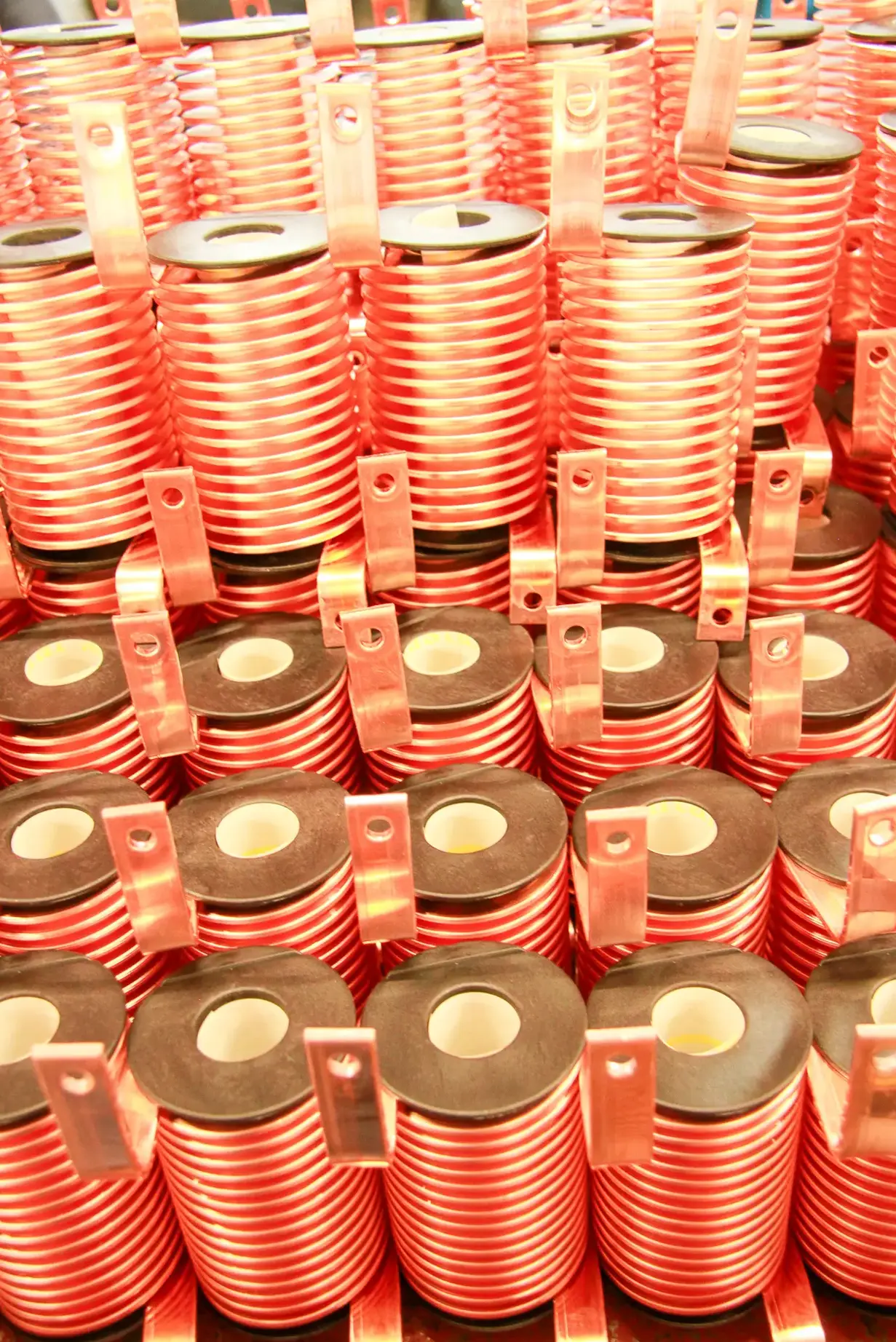

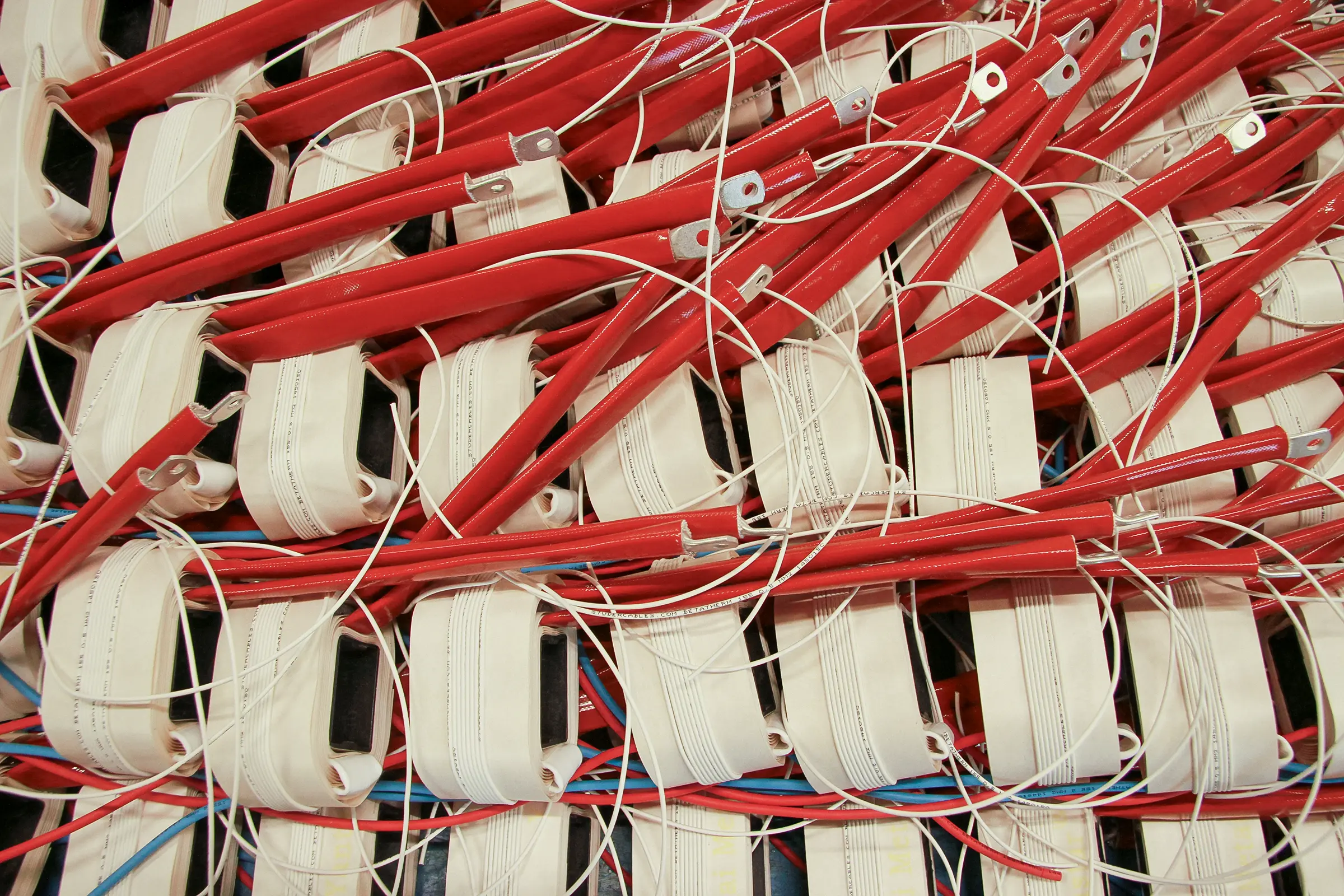

The windings of our high-frequency components are made using Litz wire or copper tape, depending on the design requirements, available space, and insulation needs.

For high-current inductors or motor windings, we use edge-wound strip, a process that has always distinguished DERBIO since its early days and is executed with our proprietary machinery.

The cores of our components are primarily made from ferrite, but we also use other materials such as sintered materials, oriented grain laminations, and amorphous materials.

Thanks to our extensive experience, we design and develop more than 80% of our automation in-house. This allows us to maintain complete control over the entire production process, providing greater flexibility and responsiveness to customer requests, while adapting to market demands. We ensure extremely high repeatability, precision, and automation in our processes.

We use the most advanced technologies and equipment to guarantee the highest quality and reliability of our products.